Editor’s note: Working Waterfront is an occasional series that captures the past, present and future of Whatcom County’s waterfront, and highlights the people behind the industry. In today’s story, learn about local boat manufacturer All American Marine.

Off the coast of Georgia in the Gray’s Reef National Marin Sanctuary, the research vessel Gannet carries scientists who map the seafloor for the National Oceanic Atmospheric Administration (NOAA). In Hawaii, the passenger vessel Poseidon carries up to 70 people on “eco-conscious” dolphin tours. Closer to home, the water taxis Sally Fox and Doc Maynard move passengers between Seattle and Vashon Island.

All of these vessels, and many more, began as sheets of aluminum inside the tall blue-gray walls of All American Marine, just off of Roeder Avenue near Bellingham’s central waterfront.

All American, one of a handful of boatyards in Whatcom County, is noted for pushing the boundaries of the shipbuilding industry. Since opening in 1987, the company has gained an international reputation for cutting-edge design of aluminum vessels and innovative hydrogen and hybrid-electric design orders. AAM manufactures high-speed catamarans, research vessels, passenger ferries and monohull cruise boats.

Their steady work contracts, paired with exclusive North American building rights to the designs of noted naval architect Nic de Waal of Teknicraft Design in New Zealand, enables customization that has gained them a preeminent international reputation in the industry.

“Nic’s naval architecture designs are really known internationally as the smoothest riding boats,” marketing manager Bronson Lamb said.

The company’s messaging touts the future of aluminum vessels, emphasizing the production of lithium-ion-powered boats and the latest in catamaran and monohull design.

In the beginning, the local boat manufacturer built fishing vessels in the old Fairhaven shipyard, to the south on Bellingham Bay. But as contracts dwindled alongside the declining fishing industry in the 1990s, the company shifted to building a broader mix of vessels.

In 2017, All-American expanded into its colossal 57,000-square-foot building on the waterfront.

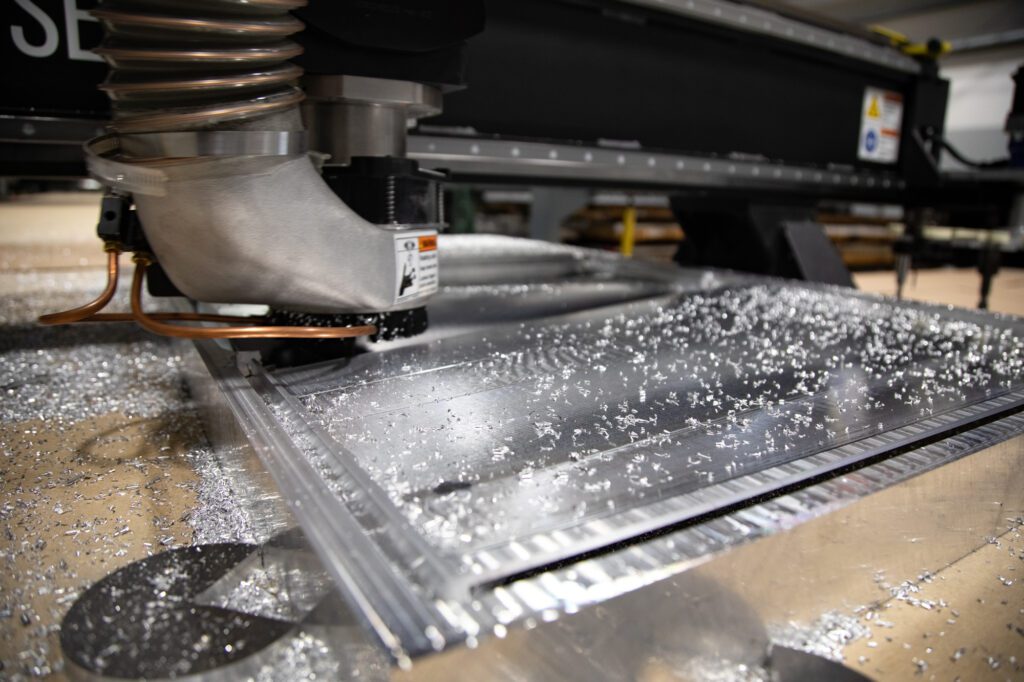

Most days of the week, the building is abuzz with welders, painters and craftsmen stepping between multimillion-dollar projects for various universities, state organizations and research companies. Sparks fly from welders’ guns as loud crashes and screams of sliced metal reverberate from the walls.

Every build is unique to fit the needs of clients, whether that be a certain length to fit a specific dock, the ability to reach high speeds, or the need to carry hundreds of passengers or incorporate important research-related equipment.

“Every customer is different,” production manager Kyler Porter said. “We don’t know who we’re going to build for until we get a contract. It can be all over the place.”

“I would say it puts us in the higher tier of shipyards in the U.S.,” business development manager Daniel Zech said.

Specifically, de Waal’s designs are known for hull shape and effective use of hydrofoils — a wing-like structure on the hull that lifts boats from the water to increase fuel efficiency and speed and reduce wake.

In a recent project for Kitsap Transit, All American built the Waterman — a hybrid-electric ferry to carry up to 150 passengers between Bremerton and Port Orchard. When loading and unloading, the vessel operates on electric battery power to reduce emissions.

In the design and build process for another series of three vessels for Kitsap Transit, the company had to consider the potential impacts to the delicate environment of the Rich Passage.

“We built [a boat] that basically creates almost zero shoreline erosion,” Porter said. “At 37 knots, there’s almost no wake that comes off a boat carrying 118 people.”

The boat is programmed so when it enters a specific geographic grid, the angle of the hydrofoils shifts and “the weight basically goes away,” Porter said. The wake is nearly eliminated, protecting the shoreline.

Beyond dabbling with hybrid-electric energy and shoreline-protecting technology, All American produced the first commercial boat powered with hydrogen fuel cell technology in the U.S. — Sea Change. It now carts up to 75 passengers around San Francisco Bay with zero emissions.

Zech said they hope to work in similar projects in the future, but only if they secure the right partners as the technology and industry develop. Ultimately, they have to connect with the customer who wants to explore alternative energy, and is willing to navigate the complications and red tape that come with getting a boat with new technology on the water.

“We absolutely want to do more hydrogen, do more electric, try out all these technologies,” Zech said. “It’s just finding a partner that’s willing to not rush the delivery.”

At a baseline, the company desires sustainable growth and aims to remain flexible to bring new projects and ideas to fruition, Zech said.

“We’re trying to progressively expand,” Porter said. “We’re trying to get more boats and our goal is to add [more] capacity than what we’re at right now.”

The company, which was purchased by Bryton Marine Group in 2021, prides itself on never having laid off an employee, Zech said. Their employment standard is a far cry from the industry’s more common practice of hiring temporary workers on short-term contracts. They work to hire full-time employees and keep them employed to maintain to continue their training and keep their knowledge within the building.

“We want to keep that local footprint,” Zech said. “We’re here. We’re active. We’re steadily trying to grow. We are always striving to create a win-win scenario for the community, for our employees, for our customers, and just try to be good stewards of all that Bellingham has.”

In March, All American will launch its newest creation: an 85-foot vessel destined for Whittier, Alaska. The client, Phillips Cruises and Tours, will take up to 150 people at a time on long-distance cruises to see glaciers and wildlife, with the special hull and hydrofoils leaving behind little wake.

Coming in March: The broader future of Whatcom County’s working waterfront.

A previous version of this story combined the work for two different projects for Kitsap Transit into one. The story was updated to reflect this change on Monday, Feb. 26, 2024 at 9:40 a.m. Cascadia Daily News regrets this error.

Hailey Hoffman is a CDN visual journalist; reach her at haileyhoffman@cascadiadaily.com; 360-922-3090 ext. 103.